Torque settings

- Rosy

- Posts: 173

- Joined: Sat Sep 14, 2019 5:50 pm

- Location: Bristol & East Devon

Torque settings

I can't find a comprehensive list of torque setting in the Archives, is there one? All I find in search are the odd setting that someone has asked for. I particularly need to know the sump plug, and oil feed/return banjo's. G9.

-

SPRIDDLER

- Member

- Posts: 8550

- Joined: Wed Sep 01, 2004 1:00 am

- Location: WEST SUSSEX UK

Re: Torque settings

Yes, details are scattered in various documents but I've never seen a comprehensive list. As far as I'm aware they weren't (or were very rarely) used at the factory. Les at Russell Motors (he has a lot of the original factory tooling) uses a box spanner with a piece of scaffold pole for the crankpin nuts on singles.

I find single spanners the best tools since their leverage is more appropriate to the nut/stud/plug being tightened. Sockets are a trap for the unwary where the same leverage ('T' bar or ratchet handle) is possible regardless of the size of the fixing.

As a bit of a romanticist I enjoy the 'art' of selecting the different sized spanners (I also have my favourites) according to the delicacy of the task. I doubt that Leonardo used just one size of brush for his Mona Lisa.

I find single spanners the best tools since their leverage is more appropriate to the nut/stud/plug being tightened. Sockets are a trap for the unwary where the same leverage ('T' bar or ratchet handle) is possible regardless of the size of the fixing.

As a bit of a romanticist I enjoy the 'art' of selecting the different sized spanners (I also have my favourites) according to the delicacy of the task. I doubt that Leonardo used just one size of brush for his Mona Lisa.

'There is a tide in the affairs of men

Which taken at the flood............'

Which taken at the flood............'

- clive

- Member

- Posts: 5664

- Joined: Mon Jan 01, 1990 12:00 am

- Location: LONDON UK

Re: Torque settings

I don't think the factory issued torque settings in 1956 when most home repairers would have been using open ended spanners or box spanners. Personally I go on spanner size. Medium spanner on the sump plug and oil feed banjos but done up with a "bit of feel" rather than as tight as you can. If you are using sockets don't use 1/2 inch drive ones as the bars that come with them are too long and you will tend to over tighten. I have invested in a set of 3/8 drive sockets and the ratchet for them is much shorter more like a medium length spanner. Both the sump plug and the oil feed would probably benefit from new fibre washers but they need to be the correct size or you are better off using the old ones.

clive

if it ain't broke don't fix

if it ain't broke don't fix

- Taid

- Posts: 710

- Joined: Mon Oct 07, 2019 3:35 pm

- Location: Shropshire UK

Re: Torque settings

off topic but within post theme .. what is the current thinking on PTFE tape for sealing oil/petrol connections?clive wrote: Both the sump plug and the oil feed would probably benefit from new fibre washers but they need to be the correct size or you are better off using the old ones.

___

Now sold ... 1956 AJS 16MS Bitsa .. HSU 414 .. rebuilt/re-registered 1987

Now sold ... 1956 AJS 16MS Bitsa .. HSU 414 .. rebuilt/re-registered 1987

-

Dixter

- Posts: 102

- Joined: Mon Oct 02, 2017 8:27 pm

- Location: Seattle area, WA USA

Re: Torque settings

Not. PTFE tape was invented to seal taper pipe threads, of which the total number on AMC bikes approximates zero.

There are many superior solutions.

Ciao, DC

There are many superior solutions.

Ciao, DC

Dick Casey

The RideNut

The RideNut

- Rosy

- Posts: 173

- Joined: Sat Sep 14, 2019 5:50 pm

- Location: Bristol & East Devon

Re: Torque settings

Works on parallel threads just the same, I've used it in all sorts of applications. Being an ex pipe fitter I know it works on taper and parallel, I've just used it to tighten the worn threads on the torpedo lights thread stems. The only thing I will say about using it on an oil/petrol thread it doesn't seem suited to it. There is Loctite 55 sealing cord, that can be wrapped around the base to form a washer that works.

- Taid

- Posts: 710

- Joined: Mon Oct 07, 2019 3:35 pm

- Location: Shropshire UK

Re: Torque settings

Thank you R .. I've used it a lot in non-oil/petrol situations and wasn't sure about it .. thanks too for the loctite info .. duly noted ..Rosy wrote:The only thing I will say about using it on an oil/petrol thread it doesn't seem suited to it. There is Loctite 55 sealing cord, that can be wrapped around the base to form a washer that works.

T

___

Now sold ... 1956 AJS 16MS Bitsa .. HSU 414 .. rebuilt/re-registered 1987

Now sold ... 1956 AJS 16MS Bitsa .. HSU 414 .. rebuilt/re-registered 1987

-

Mollbhan

- Posts: 109

- Joined: Sat Apr 06, 2019 11:52 pm

- Location: Perthshire UK

Re: Torque settings

Gas fitters PTFE tape is widely used by pressure stove and lamp collectors when assembling paraffin pressure lamps, I have very effectively used it for sealing petrol taps etc on some of my ancient two strokes.

-

asterysk_usa

- Posts: 135

- Joined: Tue Oct 22, 2019 3:42 pm

- Location: florida

Re: Torque settings

Taid wrote:off topic but within post theme .. what is the current thinking on PTFE tape for sealing oil/petrol connections?clive wrote: Both the sump plug and the oil feed would probably benefit from new fibre washers but they need to be the correct size or you are better off using the old ones.

I would estimate every Royal Enfield in India today has PTFE on the threaded fuel lines so I guess it must work ! How do I know ? I spent 3 weeks motorcycling across India coast to coast and got to see first hand how the Enfields are maintained by the local mechanics, liquid gasket compound, PTFE tape and bailing wire were in the top of every tool kit

1954 AJS 18S Cyprus export (frame decode says 1954 but many components match a 1955).

-

asterysk_usa

- Posts: 135

- Joined: Tue Oct 22, 2019 3:42 pm

- Location: florida

Re: Torque settings

When I was in the military we had a similar problem, some WWII equipment that was in current service and the tendency for the tech's to strip the threads was a frequent occurrence, primarily due to use of modern tools. It was solved by a very simple technique, the oldest tech with the least hair was chosen and given the task of hand tightening the nut/bolt using WWII hand tools. a mark was made on the nut/bolt.Rosy wrote:I can't find a comprehensive list of torque setting in the Archives, is there one? All I find in search are the odd setting that someone has asked for. I particularly need to know the sump plug, and oil feed/return banjo's. G9.

Then someone else was chosen to retighten the nut/bolt with a torque wrench until the same positioning was achieved (mark lined up perfectly)

Then all the data was tabulated (okay it was while since I left the military !) and a graph produced and that was what was used from then on

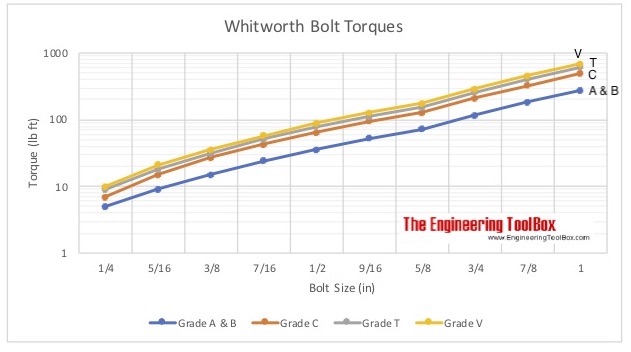

I had a quick look and found this modern day graph for Whitworth :

Probably safest to assume the lowest grade carbon steel

1954 AJS 18S Cyprus export (frame decode says 1954 but many components match a 1955).